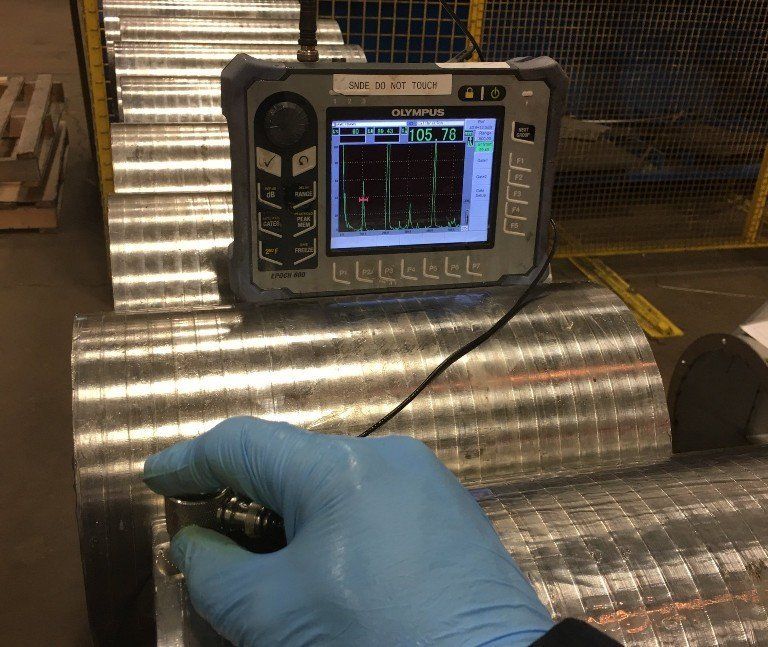

Ultrasonic Testing (UT)

Utilizing high frequency sound waves, the Ultrasonic waves are introduced in to a material by specialized equipment and ultrasonic transducers for the detection of surface and subsurface discontinuities. The reflecting and refracted sound wave signals are then analyzed to define and locate the discontinuities or defects in the materials under inspection.

Ultrasonic testing is widely used for the inspection of metals to measure the material thickness for corrosion as well as for weld inspection or the inspection of casting and forgings.

Our extensive UT services cover:

- Ultrasonic weld inspection and weld repairs

- Ultrasonic shear wave inspection

- Ultrasonic straight beam inspection

- Ultrasonic inspection of forgings

- Ultrasonic inspection of castings

- Ultrasonic thickness testing and corrosion monitoring, surveys

- Ultrasonic Flaw and crack sizing, monitoring

- Ultrasonic Shaft and journal inspections

- Ultrasonic Babbit bearing inspections

- Pipeline sleeve and fitting inspections

- Pipeline integrity inspections

- Ultrasonic tube inspections