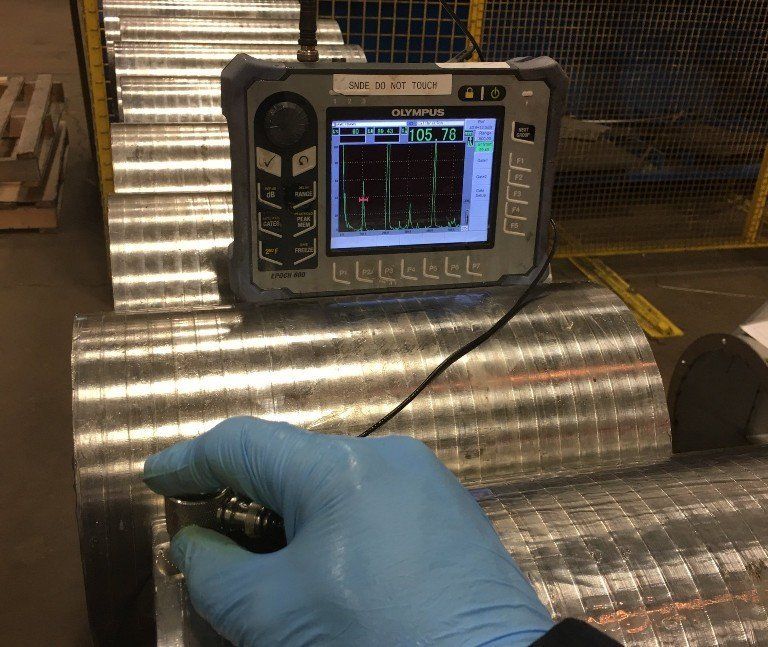

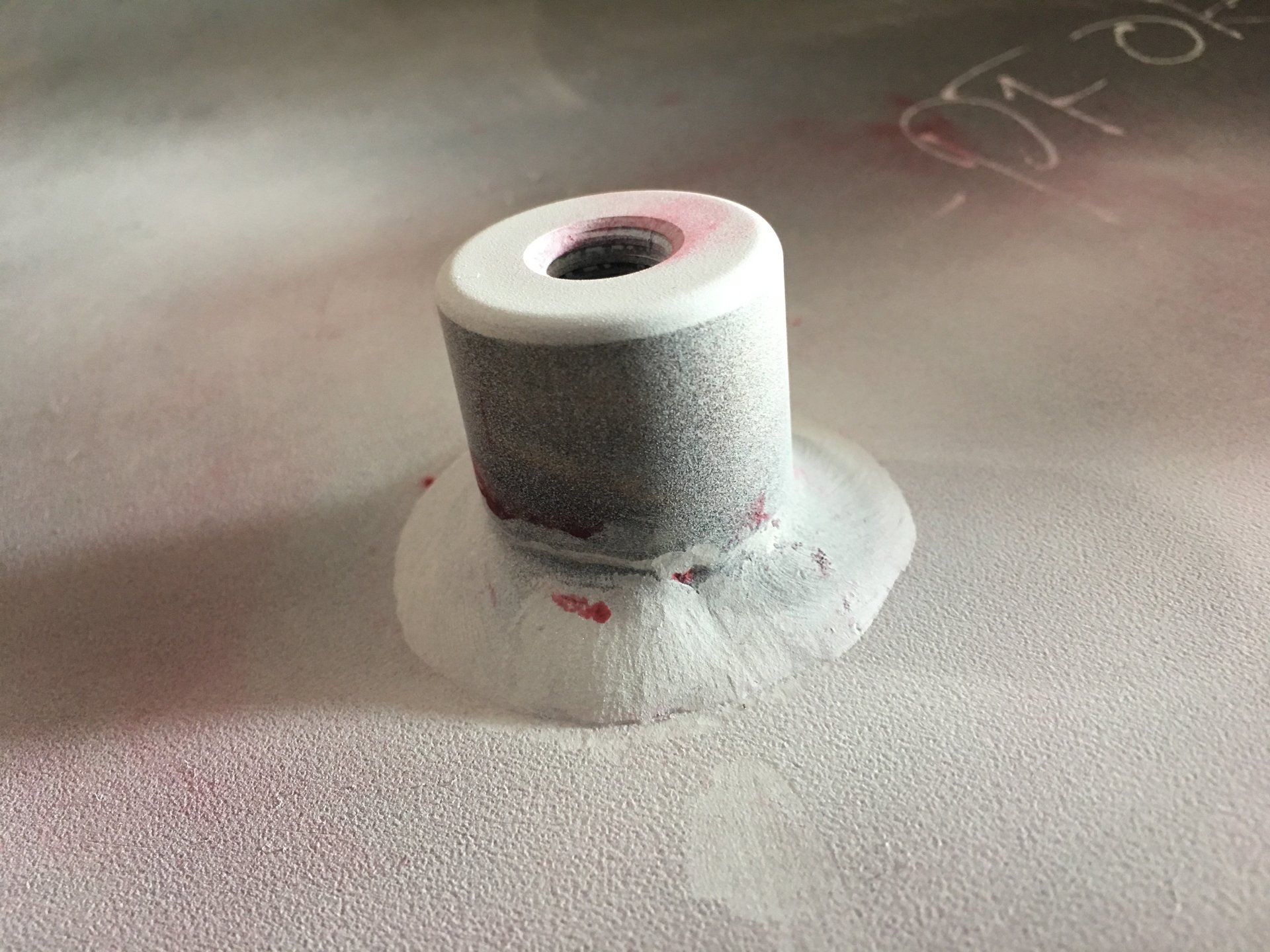

NDT INSPECTIONS

Non Destructive Testing and Non Destructive Evaluation Services

For today’s clients there are more options than ever to facilitate your inspection requirements. It is our aim to provide you with the best inspection solutions necessary to meet your needs. From complex inspections to simple tests, Specialized NDE will ensure you get quality results. Our reliable and knowledgeable NDT field technicians utilize the latest equipment, technology and procedures to perform the necessary inspections you require.

Inspections are offered in the following conventional methods:

Our NDE/NDT Inspections are performed in accordance with various codes and standards such as CSA, CWB, ASME, ASTM, AWS, API, EN.